Product Description

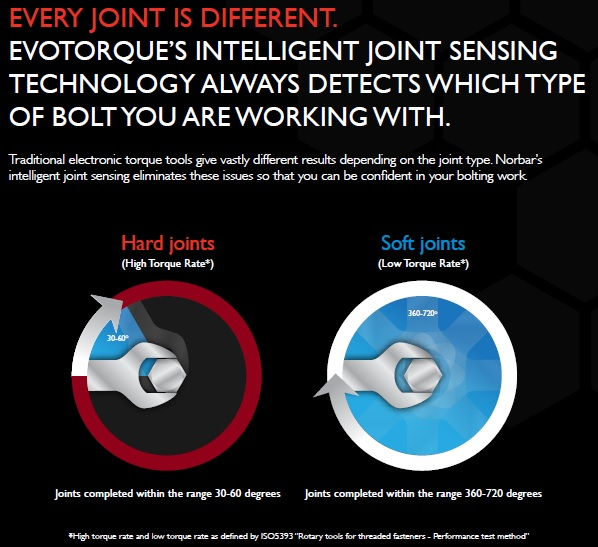

The Norbar EvoTorque 2 Electronic Torque Multiplier ET-92-3500-110 has a 1'' Drive and provides a range of 260-2580 Ft Lbs or 350-3500 Nm. The EvoTorque® 2 is an electronic torque tool designed for accurately applying torque to threaded fasteners. Tools are factory calibrated to ±3% of reading. The unique ‘intelligent joint sensing’ technology of the Norbar EvoTorque continually measures the joint during tightening and, when necessary, employs dynamic braking to avoid torque over-shoot due to motor inertia. Consequently, EvoTorque® can apply torque accurately over a wide range of joint rates from hard (high torque rate) through to soft (low torque rate). All EvoTorque® tools are highly tolerant of supply voltage and frequency variation. When the tool runs, it will run accurately. If the supply voltage is outside of tolerance then, as a safety feature, the tool will be prevented from starting.

The EvoTorque® 2 has the ability to memories multiple targets, work IDs, user IDs and readings. The tool has three modes of operation: Torque, Torque and Angle and Torque Audit. The unique Audit Mode is a sophisticated feature for testing pre-tightened bolts with minimal impact on the original fastening torque and can provide quality control data for monitoring joint performance over time.

Features:

- Each Norbar EvoTorque electronic torque multiplier is supplied with a traceable calibration certificate

- Torque, Torque & Angle, Torque & Angle with Final Torque or Torque Audit Modes

- 'Usage' counter gives the ability to see the amount of times the tool has been used since the last reset

- "Operation Direction" designed primarily for undoing bolts. When doing sequence tightening, it is now possible to undo an incorrectly tightened bolt without interrupting the sequence

- 2 Stage Tightening gives faster application of a Snug Torque & Angle Target

- "Turn Angle" option can be used to check if bolts have already been tightened in an assembly process

- Allows tool integration into third party control systems

- Maximum Audit Mode target angle increased to 720 degrees

- Ability to produce and store real time graphs via EvoLog

- 2 different lock levels, lock level 1 as per previous lock, lock level 2 will not allow user to exit the run screen or change the target

- 1" Square Drive

- 6 rpm

- Tool Weight of 12.85kg

- Calibrated to 20% - 100% of tool's maximum capacity

- Operational targets can be set from 10% of tool capacity